This page is an attempt to collect all relevant information about the Shimano Alfine Inter 11 internal gear hub, meant for people considering purchasing it, finding compatible parts, maintaining and troubleshooting the hub. This page is a living document that will be updated and expanded as time progresses. If you find any factual errors or omissions, please contact me.

I made this page because information regarding this hub scattered throughout the internet. Throughout the text you can also find my personal experiences with the hub, I have tried to keep these separated from the factual information.

Tell me how (un)reliable your hub is!

To provide better information about the long term reliability of this hub I am looking for input from you. If you have used this hub for more than a year (the longer the better), or have any failures to report please contact me and tell me how much distance you covered, and what maintenance schedule was kept. I am especially interested in reports from people who service multiple hubs.

History

When it comes to internal gear hubs there are many options, from different manufacturers, but as soon as you want a slightly larger range that will allow you to climb some serious hills there are not so many options left.

The better known internal gear hub is the Rohloff Speedhub 500/14 with 14 gears and a total range of 526%, while all other internal gear hubs don't go much beyond 300%. The Rohloff carries a hefty price tag of somewhere around 1000 euros.

Japanese bicycle part manufacturer Shimano was already offering eight speed internal gear hubs in their Nexus and Alfine product lines. They realized there was a gap in the market for a high-end internal gear hub with more gears, but at a lower price point than the Rohloff hub.

In 2010 Shimano introduced the Alfine Inter 11, which has a range of 409%, which makes it more suitable for climbing hills. Originally priced around half the price of a Rohloff, you can now (2017) find it for around 250 euros, which makes it a very attractive option. The Di2 electronic version sets you back around 300 euros.

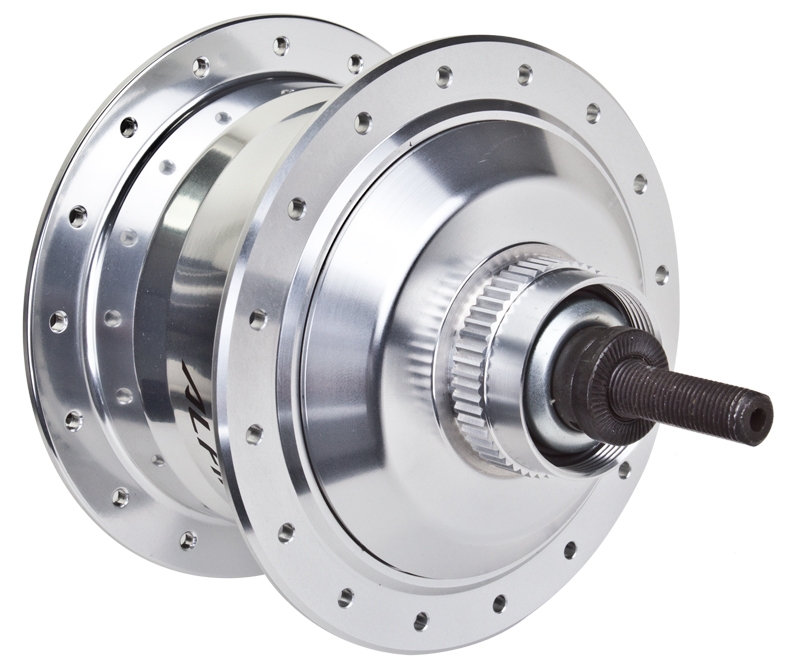

Specifications

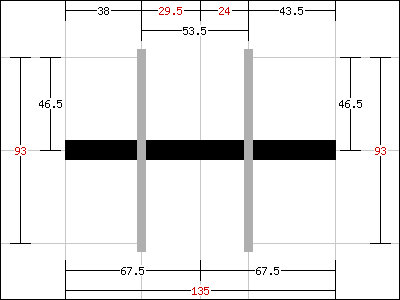

| Gears | 11 |

|---|---|

| Color | Black or silver |

| Gear range | 409% |

| Fork end width | 135 mm |

| Spoke holes | 32 or 36 |

| Shifting type | Mechanical or electronic (Di2®) |

| Weight | 1744 gram |

| Disk brake mount | Shimano Centerlock® |

| Chainline | 42.7 mm |

| Axle diameter | 9.5mm (3/8") |

| Spoke Hole Diameter | 2.9 mm |

| Flange Diameter | 93 mm (left & right) |

| Left Flange Offset | 29.5 mm |

| Right Flange Offset | 24 mm |

Measurements by Karl Stoerzinger

Gear ratios

The Shimano Alfine Inter 11 has a total gear range of 409% spread out over 11 gears. It does not have a gear with a 1:1 ratio. The steps between each gear are almost equal, except the lowest gear, the step is almost twice as big, so it acts as a "granny" gear for climbing steep inclines.

| Gear | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ratio | 0.527 | 0.681 | 0.770 | 0.878 | 0.995 | 1.134 | 1.292 | 1.462 | 1.667 | 1.888 | 2.153 |

| Step size | 29.22% | 13.07% | 14.03% | 13.33% | 13.97% | 13.93% | 13.16% | 14.02% | 13.26% | 14.04% | |

| Range | 100% | 129% | 146% | 167% | 188% | 215% | 245% | 277% | 316% | 358% | 409% |

| Cable pull (mm) | 5.1 | 5.2 | 4.8 | 5.3 | 4.8 | 6.6 | 5.3 | 4.7 | 5.2 | 5.9 |

Variants

The Shimano Alfine Inter 11 comes in different versions:

- Silver/black

- 32/36 spoke holes

- Mechanical/Di2 electronic shifting

- Revision

Looking for list of SKU's

I am looking for a list of EAN or SKU numbers for the different variants. If you have such a list that you want to share, please contact me.

| Shimano product ID | Year | Description |

|---|---|---|

| SG-700 | 2011 - 2017 | Mechanical shifting hub |

| SG-705 | 2013-? | Electronic (Di2) shifting hub |

| SG-7001 | 2017 - ? | Juy 2017 revision |

| SG-S7001-11 | 2018 - ? | Mechanical shifting hub for Shimano eSteps electrical assist, 2018 revision |

| SG-S7051-11 | 2018 - ? | Electronic (Di2) shifting hub for Shimano eSteps electrical assist, 2018 revision |

Revisions

In July 2017 Shimano released an updated parts list (PDF). The document contains a list of parts for the SG-7001 hub, which is the first revision of the hub after the initial release of the SG-700 in 2010.

The document shows a list of all the parts. Most parts the same (indicated with letter "A" in right column). The following two parts are marked with a "B" meaning that the parts are interchangeable but differ in materials, appearance, finish, size, etc.

- Two parts Internal Assembly (Axle Length 187 mm)

- Driver Unit

At this point it is not known how these parts exactly differ from the original. If you have any information about this revision, please contact the author.

Shimano Alfine Inter 11 Di2 for Electronic Shifting

In 2013 Shimano released a new line of Shimano Alfine Inter 11 hubs for electronic shifting. They have the same gears on the inside. But are distinguished by a blue line running across the hub shell. Instead of a cassette joint, the gears are moved by a electric motor unit (MU-S705) which is powered by a battery. Shifting is done using a wireless electronic shifter.

For bicycles with derailleur shifting systems the main advantage is that shifting is faster. For the internal gear hub the flexibility in shifter choice is a big advantage. You can use any style of handlebar, with the different electronic shifters that are available.

Adding Electronic Shifting to a Mechanical Hub

If you already own a bicycle with a Shimano Alfine hub (SG-700) and want to know if it is possible to upgrade to electronic shifting there is bad news: According to Shimano it is not possible to use the motor unit. The reason is that the hub (SG-700) contains a return spring. When shifting down, the shifter pulls the cable and tensions the spring. When shifting up cable tension is released and the spring pushes the hub in the right gear. With the Di2 hub (SG-705) the motor unit turns into different direction for shifting up and down. It would require more power for the motor to shift down and tension the spring.

- 3D animation video showing the basic functionality of Alfine 11 Di2 electronic shifting hub.

- Video of bench test of Alfine 11 Di2 system.

- Action cam footage of Alfine 11 Di2 hub.

Electronic Di2 Shifters

In 2014 Shimano released the Di2 version of the Alfine 11 hub, which is Shimano's electronic shifting system which comes with a wireless electronic shifter (SW-S705) with push buttons. The advantage of this shifter is that can be mounted on any kind of handlebar, including drop bars.

Super SLR Alfine Di2 Brake Lever (BL-S705-L/R)

For bicycles with drop bars Shimano also sells a brake lever with integrated electronic shifter. The last letter in the product code (L and R) indicated if it is meant to mounted on the left, or right side of the handlebar.

The left lever is just a brake lever, only the right one has shifting functionality built in. It can be used with cable actuated short pull brake calipers (road bikes with thin tires). For compatibility with other brake types you need something like a travel agent or something else. These options are more complex than getting the appropriate brake levers and using the push button shifter (SW-S705) instead.

It is not possible to use an electronic shifter with the mechanical version of the hub, the entire hub has to be replaced.

Compatibility

Compatible Frames

The Shimano Alfine 11 requires the rear fork end to be spaced 135 mm. It can be used with horizontal or vertical fork ends. When using it with vertical fork ends you need some way to adjust the chain tension. If the frame does not have an adjustable drop out or eccentric bottom bracket you can can use a cable tensioner. Shimano sells a Alfine branded chain tensioner (S510), but others also exist.

Modifying an Alfine Inter 11 hub to fit a narrow frame

The hub shell of the Alfine 11 hub is narrow enough to fit in a 120 mm fork end, one reader modified his hub to fit a Specialized Langster track bicycle with a 120 mm wide horizontal fork end. Together with a cycling enthusiast at an local engineering shop, using trail and error, they were able to make the hub fit without modifying the frame.

The process involved grinding down the original Shimano parts using CNC machinery. The left outer cone nut was removed completely, the sides of the right outer cone nut were ground down to make it flat enough to fit through the frame. The cone nuts are part #25 in the internals schematic.

The flat sides of the axle were extended to go further towards the middle of the axle. A custom made two pronged washer is added to the outside of the fork on the left side, this replaces the original non-turn washer. Another nut is added before the original dome nuts at the axle ends.

Compatible Mechanical Shifters

When introduced there was only a trigger shifter, since then several other options have become available, but options remain limited.

For a shifter to work with the Alfine Inter 11 it needs to be indexed with 11 steps. The amount of cable pull varies slightly per gear. A shifter needs to be specifically designed for this hub to work. A non-indexed (friction) shifter is not recommended as you need a very specific amount of cable pull in order not to damage the gear selection pawls inside the hub.

Shimano Trigger Shifter SL-S700

The Shimano SL-S700 "Rapidfire" trigger shifter is the default shifter. It has two levers. The thumb lever shifts down, the index finger shifter shifts up. It has a few nifty tricks. You can push the top trigger in both directions to shift up, which means you can also use your thumb and keep your finger on the brake lever. Another nifty feature is that you can double shift by pushing the trigger further after the first click, it will click again and you will shift two gears.

- Shimano Trigger shifter SL-S700 on Amazon.com

- Shimano Trigger shifter SL-S700 installation guide (PDF)

The shifter has a bright orange indicator which shows you the current gear, with markings at 1, 6 and 11. It will fit on a handlebar with an outer diameter of 22.2 mm. The grip around the handle bar should not have an outer diameter greater than 34 mm.

The shifter outer cable needs to have an outer diamater of 4.0 mm. The inner cable is 1.2 mm in diameter with a drum shaped ending, an 1.1 mm inner cable will also work (even better according to some).

Personally I like the trigger shifter a lot more than I initially thought I would. It works very quickly and is easier than a twist shifter as it only requires the flick of a finger, as opposed to moving your whole hand. This makes it easy to shift with cold/wet hands and gloves.

Third Party Mechanical Shifters

Since Shimano only has the trigger shifter as mechanical version of the hub, various manufacturers have started to produce compatible shifters that fit better on different types of handlebars.

Versa Road Shifter

The Versa Road Shifter is the only mechanical shifter compatible with drop bars. The shifter has an integrated brake lever. I have seen mixed reports about it's quality.

Genesis used this shifter on their Day One 2012 bicycle. On reader who owned thsi bicycle wrote that the Versa shifter failed after three years, the replacements failed again several months later.

This product has been discontinued in 2016.

Microshift SB-N110

The Microshift SB-N110 is a shifter for dropbars with integrated brake lever. It is sold in a set with a matching (left side) brake lever. It looks a lot like the discontinued Versa Road Shifter. The reason is that these are essentially the same product. Microshift manufactured most of the shifter for Versa. When Versa discontinued the product Microshift started selling the complete shifter themselves.

FYI, the main parts of Versa for Alfine 11 shifter was supplied by microSHIFT, Versa modified some parts and to have the shifter compatible with Alfine 11 which we didn’t provide. Unfortunately Versa stopped the supplying of this product in last year, but we decided to keep on this version after some talk with customers. The main mechanism is the same, we just have a minor change in some details.

Regards

microSHIFT

Source: Topic Shimano Alfine 11 - Longer term reliability at Cycling UK Forums

Jtek Bar End Shifter

Jtek manufactures an indexed bar-end shifter for internal gear hubs. There are various versions, one of them is compatible with Shimano's 11 speed hub.

Jtek Thumb Shifter

The Jtek thumb shifter is not really a separate shifter, it is the same bar end shifter as mentioned above, but with an additional mount adapter that allows you to clamp it around a 22.2 mm (straightish) handlebar. It is sometimes sold as a kit with the shifter.

Grip & Twist Shifters

There are no grip/twist, bar end or down tube shifters available at the moment of writing.

Note: It is a bad idea to use non indexed (friction) shifters, when the amount of cable being pulled is not within the acceptable tolerance, it can damage the hub.

Brake Compatibility

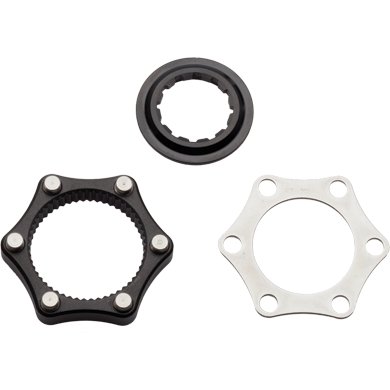

The Shimano Alfine Inter 11 has an interface for Shimano Centerlock disc brake rotors. There are various third party adapters for using rotors with 6 bolts (ISO). Installing a disc rotor requires a special tool.

It is possible to use any disc brake caliper that fits the frame and rotor. This means that you don't need to stick with Shimano. It is possible to use mechanical and hydraulic disc brake calipers and levers from any manufacturer; Avid, Hope, Magura, Tektro, TRP, etc. will all work.

The Shimano Alfine Inter 11 can also be placed in a wheel/bicycle with any kind of rim brakes. It comes with a cap that covers the Centerlock® interface, when it is not used.

Unlike the Shimano Nexus hubs there are no versions of the Shimano Alfine Inter 11 with coaster or roller brakes.

Belt Drive Compatibility

Like most other internal gear hubs the Shimano Alfine Inter 11 can be made to work with belt drive systems that replace the chain with a belt.

The Gates Carbon belt drive is the most popular option at the moment. This requires a frame where the right seat stay can be opened up to install the belt. It is sometimes possible to have a frame builder convert a frame.

Compatible Wheels

The hub comes with either 32 or 36 spoke holes and can be laced into any rim with the same amount of spoke holes.

20" Loop Wheel

An alternative to a traditional spoked wheel is the Loop Wheel®, which uses carbon fiber loops to add suspension inside the wheel. At this moment (2017) Loop Wheel does no longer appear to offer a wheel with the Alfine Inter 11 hub.

Compatible Chains

The chain that can be used depends on the sprocket. There is no Alfine branded chain. The Shimano Alfine sprockets work with single speed bicycle chains. The Alfine, Nexus, and most other modern sprockets are of the narrow type. This means a narrow chain 3/32" (pin length of 6.7 to 7.8 mm) will fit. A wider 1/8" chain will also fit, but is heavier.

It is also possible to use 7, 8 and 9 speed chains. So basically, any bicycle chain will work, as long as it is not a 10 or 11 speed chain for derailers.

So what is the best chain for the Alfine 11? Shimano suggests a 7 or 9 speed chain, but that is because they don't offer anything else. Sram makes some pretty affordable chains which are generally preferred because they come with a master link for easy connecting, unlike Shimano. KMC has some chains especially for high-end internal gear systems, which are quite a bit more expensive, but does not explain what justifies the price.

So what to choose? As long as you are buying from one of these brands you are getting a quality chain. A master link is nice to have. Anti rust coating or nickel plating helps if you ride in wet conditions. You may even be able to save a few grams with a light weight chain. Beyond that, just go for the best price and best looks.

Environment

Low temperatures

As far as I can tell Shimano does not specify an operating temperature for the Alfine Inter 11 hub. Temperature has the biggest effect on the lubrication oil inside the hub. I was unable to find any reports of oil inside the hub becoming less viscous or freezing in such a way that it becomes a problem.

One user writes the following:

I've used an Alfine this winter in temps from -30 to -40 deg C for 45 - 90 mins at a time with the bike indoors in between rides. So far I haven't had an issues at all.

The Alfine 11 is different from the Alfine 8 in this regard. The 8 speed hub uses thicker grease as lubricant which on which low temperatures have a stronger effect.

Those worried about oil in colder conditions can opt to replace the standard oil with something thinner at their own risk. Rohloff all seasons oil can be mixed with an equal part of with Rohloff cleaning oil to create a winter oil that works down to minus 30°C. It is likely that the same method can be applied to the Shimano Inter 11 hub.

Reports of the hub being unable to shift in freezing conditions are caused by moisture in the shifting cable, or at the cassette joint where the cable exits. This can occur with any cable based shifting system. Th e solution is to lube the shifting cable with a lube that does not freeze as easily as water (usually a thin oil inside the cables, and something thicker around the joint). Preventing moisture from getting in the cable by storing the bicycle in a dry place helps. Using the Di2 variant with electronic shifting will also not have this problem, but the batteries can also be negatively affected by extreme cold.

- Rohloff FAQ (See question regarding Low temperature/winter shifting issues)

- Cycling UK Forum: Alfine "sticking" in sub-zero temperatures

Acquisition

You can buy a bicycle that comes pre-installed with this hub. There are too many manufacturers to list here who offer bicycles with the hub and shifter installed. If you have a bicycle or frame and have verified it is compatible you can build, your own wheel, or have a wheel built for you with the hub in it, and install in in your bicycle. You can do this yourself, or any bike shop who employees a competent wheel builder.

You will probably not find the Alfine 11, or any internal gear hub on the shelves of your local bike store. Maybe they can order it for you, but you can also buy it online yourself. Some large online shops that sell bicycle components will have it, but also Amazon.com and sometimes you can find even better deals for brand new hubs on Ebay.

Make sure you get the right version. Prices can vary per version. If you don't mind the color or are flexible about the amount of holes you can find better deals. Also check what accessories are included. Often it comes with a shifter. You will also need at least a sprocket and small parts kit. Don't forget the oil and an oil change kit that you will need pretty soon afterwards.

| Model no. | Shifting | Color | Holes | Link | |

|---|---|---|---|---|---|

| SG-S700 | Mechanical | Black | 32 | View on Amazon.com | |

| SG-S700 | Mechanical | Silver | 32 | No link at the moment | |

| SG-S700 | Mechanical | Black | 36 | View on Amazon.com | |

| SG-S700 | Mechanical | Silver | 36 | View on Amazon.com | |

| SG-S705 | Electronic | Black | 32 | View on Amazon.com | |

| SG-S705 | Electronic | Silver | 32 | View on Amazon.com |

Installation

After you have made sure that your bicycle is compatible, you need to get the hub and all necessary parts. It's best to installation guide (PDF) carefully. This will give you a batter idea of the required parts and tools.

Additional parts required

The hub can be sold bare, with shifter, or as a complete set. To convert a whole bicycle you will need the following parts, in addition the hub:

- A compatible shifter with inner and outer shifting cable.

- Small parts kit with cassette joint and non-turn washers.

- Sprocket, see the chapter sprocket replacement for the options.

- Rim and right amount and length of spokes to build a wheel.

- Optional (for vertical dropouts): chain tensioner.

- Optional (for disc brakes): Centerlock disc brake rotor and adapter.

The small parts kit includes a green and blue non turn washer which are meant for frames with vertical dropouts. If you have different dropouts you need to purchase the washers separately. If you have vertical dropouts you also need to have some kind of chain tensioning system.

Chainline

With an internal gear hub you ideally want the chain to go straight to the crank. You can tweak the chainline by using dished sprockets that will move the chain either in and out. At the bottom bracket you can add spacers to move the chainring left and right. You can also use the Shimano Alfine crankset to get the correct chainline without having to make any tweaks.

- Shimano Alfine SG-S700 Installation guide (PDF)

- Shimano Small Parts Set for Alfine inter 11

- Shimano Alfine 39T crank Black

- More information on installing Shimano internal gear hubs from Sheldon Brown

Installing a Disc Rotor

To install a Centerlock rotor directly on the Centerlock interface a rotor spacer is needed to secure it. The spacer is placed between the rotor and the lock ring. This part can sometimes lead to some confusion, it may not be included when you buy the hub. The rotor spacer has part number Y37R82000 and can be bought separately.

If you want to use 6-bolt disc rotor you need to install an adapter. There are many different adapters sold by different manufacturers. The bolts are relatively close to the Centerlock interface. Some adapters require an extra spacer which has a smaller outer diameter than the rotor spacer. The size of the bolts will also affect how wide and thin the spacer needs to be. Some adapters like one made by DT Swiss Proline adapter avoid this problem by using a design without bolts and a custom lock ring.

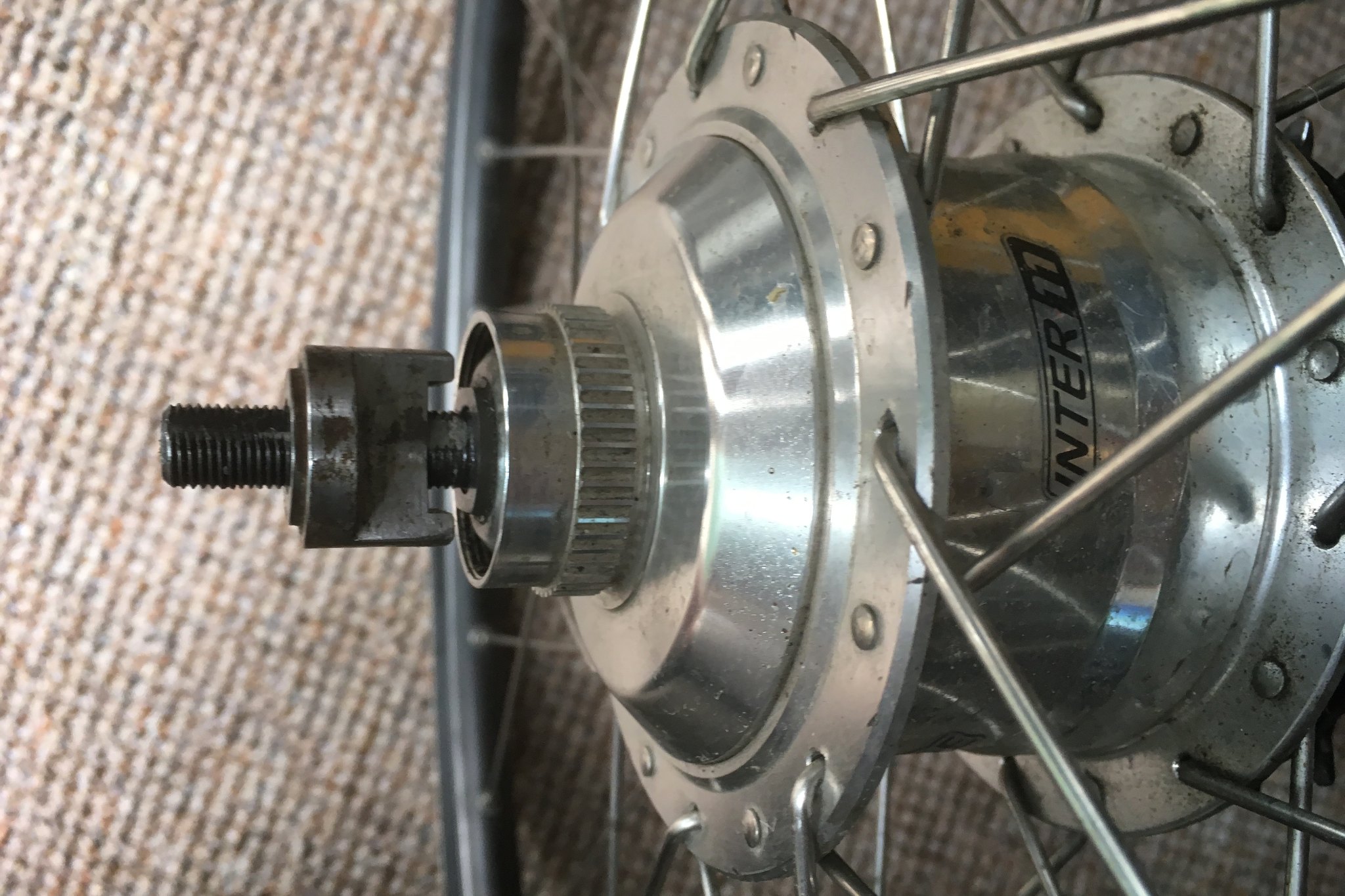

To fasten the rotor a lock ring is used. This lock ring requires a special tool that will work in Shimano cassettes as well. Not every Centerlock/cassette tool will work. Some of them have a guide pin in the middle for extra stability. This pin will only work with hollow axles. The Shimano Alfine Inter 11 has a solid axle. You will need a tool which does not have this pin.

Below there are several links to the right tools that can be used on the lock ring. They are meant to fit on 1 1/4" socket wrench. Some are too short for the axle of the hub. In that case, use a wrench on the outside of the tool. Most of them have a hexagonal section which allows you to grip it there.

- Topeak Cassette/Freewheel Remover Tps-Sp39 on Amazon.com

- Park Tool Cassette/Rotor Lockring Removal Tool - FR-5 on Amazon.com

- IceToolz Cassette Lockring Tool on Amazon.com

- Avenir Cassette Lockring Tool on Amazon.com

- M-Wave Cassette-sprocket-remover on Amazon.com

Maintenance

Much of the maintenance of the Shimano Alfine Inter 11 can be done by the user. Shimano's official maintenance manual contains step by step instructions with pictures.

Cable Adjustment

If you have problem with skipping, or shifting into certain gears the cable may need some adjustment. The shifter cable can stretch a bit over time (or the outer cable compresses), requiring you to pull it tighter.

Just like other internal gear hubs from Shimano you adjust the cable with a barrel adjuster on the shifter. First shift to the middle (sixth) gear and then look at the hub, there are two yellow dots that should line up, turn the barrel adjuster until they line up.

Since the hub has more gears than any other Shimano hub the alignment has a smaller sweet spot that can be difficult to find. A damaged inner or outer cable can also cause shifting issues. If your hub suddenly has problems with shifting it can be an indication that the cable is about to break and needs to be replaced.

Some people have reported that for their hub shifts better when the yellow dots don't line up exactly.

My Own Experience

The shifting cable on my bicycle has not been out of alignment. My girlfriend's bicycle had trouble shifting into the lowest gear on our two week trip to England (start of second season using the hub). A slight adjustment with the barrel adjuster on the shifter solved the issue.

Cable Replacement

How to replace the shifting cable depends on the shifter used. Instructions for replacing the cable with the (standard) Shimano trigger shifter SL-S700 can be found in the installation guide.

You can use a standard/universal shifting inner and outer cable, but of course Shimano sells appropriate ones as well. By far the hardest part is that you need to secure the fixing bolt unit on the inner cable exactly 184 mm from the rubber cover. Shimano sells a special tool (TL-S700) for this. Whether it is worth the price is for you to decide.

Periodic Oil Change

Unlike most other internal gear hubs the Alfine Inter 11 uses oil for lubrication, rather than grease. The oil can be replaced through a hole with a syringe.

Shimano sells an oil change kit with syringe, cup and oil. This kit is quite expensive, but you can't just use any oil, as it needs to have a certain viscosity and not damage the rubber seals inside the hub. Using any other oil will void the warranty.

Nevertheless, some people are using Rohloff oil, which is sold in larger quantities and is significantly cheaper. The Rohloff syringe also fits the Alfine Inter 11 hub and procedure is exactly the same. As an added bonus the Rohloff oil is biodegradable, while Shimano's oil is (probably) not.

My Own Experience (with Rohloff Oil)

As the user manual suggests, I replaced the oil of my hubs after 500 kilometers. The oil that came out was full with sparkling aluminum specks. I used Rohloff oil which has separate oils for rinsing and lubrication. The rinsing oil also had aluminum specks in it.

After about a year I started to notice a faint crackling noise coming from the rear of the bicycle. The sound was only present in sixth and seventh gear, indicating that the sound was coming from inside the hub. When changing the oil at the end of the season between 10 and 15 milliliters came out, the rest had leaked out. There were no noticeable aluminum specks during the second oil change. Immediately after the oil change the crackling sound persisted, but it soon subsided, and the hub has been smooth and quiet since.

- Service Kit for Shimano Alfine 11 Hub & 50 ml oil on Amazon.com

- 50 mL Shimano Oil on Amazon.com (one change)

- 1 L Shimano oil on Amazon.com (20 changes)

- Rohloff Speedhub Oil Change Kit

Cleaning around the hub

Although not required for its operation, it might be a good idea to clean your bicycle once in a while. This is good opportunity to do a thorough inspection and make some small adjustments. A clean bicycle also keeps your hands clean when you have to touch it for transportation or repairs.

The Alfine 11 hub is in particular dirty area of the bicycle. It is normal for some oil to leak out around the seals on the right side, and then there is the chain which also usually one of the dirtier parts.

A thorough way to clean the hub is to remove the wheel from the bicycle, then disassemble much of the hub and use an ultrasonic parts cleaner to clean the parts. If you want to leave the wheel in the bicycle, I recommend the following method:

Useful cleaning supplies

- Rag; a cloth made out of fabric that can absorb grease and grime.

- Small blunt stick for wrapping the rag around, preferably made out of food or plastic that will not scratch anything.

- Spray bottle with mild degreaser liquid.

Cleaning instructions

- Start with a dry rag and wipe down the spokes, which are usually covered by oil and dust.

- Take the rag, holding one end in each hand and put it between the hub shell and sprocket. Move up and down (like flossing teeth) until there is no more visible grease on the seal when you look from above. Now rotate the rear wheel a little bit and clean until you have gone all the way around.

- Put a tip of the rag around the axle on the right side between the cassette joint and the frame and again use a flossing motion to clean all the way around.

- Wipe of any grease from the cable. Push the pulley handle to get some slack on the cable if you want to clean it around the end.

- To clean the right side of the sprocket wrap the rag around the tip of your finger, or a stick (if your fingers are big) and wipe the sprocket while rotating the pedals backwards. Clean the teeth on the front where there is no chain on them.

- Now that the worst dirt is gone, work on the plastic dust cap. This is where a lot of oil accumulates. First wipe it down as much as you can. Pull it out towards the sprocket. Underneath you will find more oil. Wipe it down as much as you can. There are many nooks and crannies here. Some mild degreaser may be applied, but be careful not to get it on the chain or anywhere else. When sufficiently cleaned, put the dust cap back on.

- The hub shell can be cleaned with a damp cloth, or some liquid soap if you want to be thorough. Pay attention to the edge of the spoke nipple. A small (tooth)brush may help cleaning around the spoke holes. Dry if off with soft cloth for a shiny finish.

- The left side is not as dirty as the right side. There is still dust, but not as much oild and grease. There are still many books and crannies. Be careful around the disc brake rotor, the edges are sharp like a knife and can easily cut your fingers. Try not to get any oil or grease get on the rotor. If you do, use a degreaser to clean it off.

Sprocket replacement

You can replace the sprocket on the Alfine hub once the teeth wear out. If you are satisfied with the range of your gears you should get one with the same amount of teeth.

If you want to make climbing mountains easier, you can replace the sprocket with a large one with more teeth. If you want to go faster, replace it with one with less teeth.

The Alfine sprocket (S500) comes in only 18 or 20 teeth, and has a plastic chain guard around it. Shimano recommends using this sprocket when using the CT-S500 chain tensioner, which you would only need if your frame has vertical drop outs.

If you have another way of tensioning the chain you can also use sprockets meant for the Shimano Nexus hubs on the Alfine hubs. These sprockets come with 16, 18, 19, 20, 21, 22 or 23 teeth, they are often a bit cheaper as they don't have the plastic chain guard.

The Nexus sprockets are dished, meaning that depending how you put them the the teeth on sprocket go inside or outside. This allows you to line it up with the chainring on the crank for a better (straight) chain line.

Shimano recommends a ratio of around 1.9 for the chain ring and rear sprocket. Meaning that the chain ring should have almost twice as many teeth as the rear sprocket. A lower ratio means that the whole gear range is lowered, making it easier to climb steep ascends. It also allows you to apply more torque on the mechanism inside the hub, going below the manufacturer recommendations may increase wear or increase chance of failure.

My own bicycle came with a 18T Nexus sprocket installed with a 32T chainring from the factory, that is a ratio of 1.78, below what Shimano recommends. There seems to be no adverse affects after two years. I have since then installed a 19T on my girlfriend's bicycle (ratio 1.68).

Two different readers messaged wrote to me to tell me that they used a 22T sprocket with a 32T chainring which have a ratio of 1.45. One did 5,000 kilometers, the other 14,000 kilometers at the moment they wrote to me and did not run into any issues so far.

My take on this is that the recommended ratio of approximately 1.9, is really just rather vague, and just a recommendation. If you need a lower gearing range, don't let this recommendation stop you and just install a larger rear sprocket.

- Shimano Alfine Inter 11 Sprocket Swap step by step instructions

- Shimano Nexus 16T Sprocket on Amazon.com

- Shimano Nexus 18T Sprocket on Amazon.com

- Shimano Nexus 19T Sprocket on Amazon.com

- Shimano Nexus 20T Sprocket on Amazon.com

- Shimano Nexus 21T Sprocket on Amazon.com

- Shimano Nexus 22T Sprocket on Amazon.com Black

- Shimano Nexus 23T Sprocket on Amazon.com Black

Chain Tension

Because there is no derailleur to hold the chain tension the Shimano Inter 11, like any other internal gear hub requires another method of keeping the chain tensioned.

Bicycles that come equipped with a internal gear hub usually heave adjustable or horizontal fork end, or come with an eccentric bottom bracket to keep the chain tensioned. These require regular adjustment as the chain stretches over time.

Compatible chain tensioners

For bicycles with vertical drop outs Shimano also offers an Alfine branded chain tensioner (CT-S500) which replaces the derailleur. The CT-S510 is smaller, but according to one review also requires regular adjustment.

Various other manufacturers sell chain tensioners for single speed and internal gear hub bicycles that will also work with the Alfine Inter 11.

View product on Amazon.com

View product on Amazon.com

Efficiency

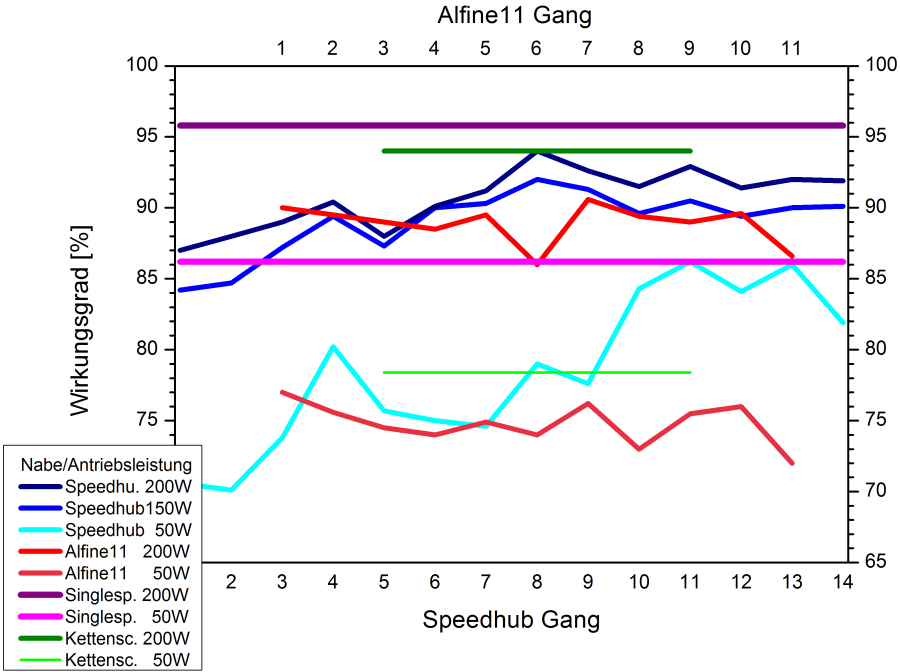

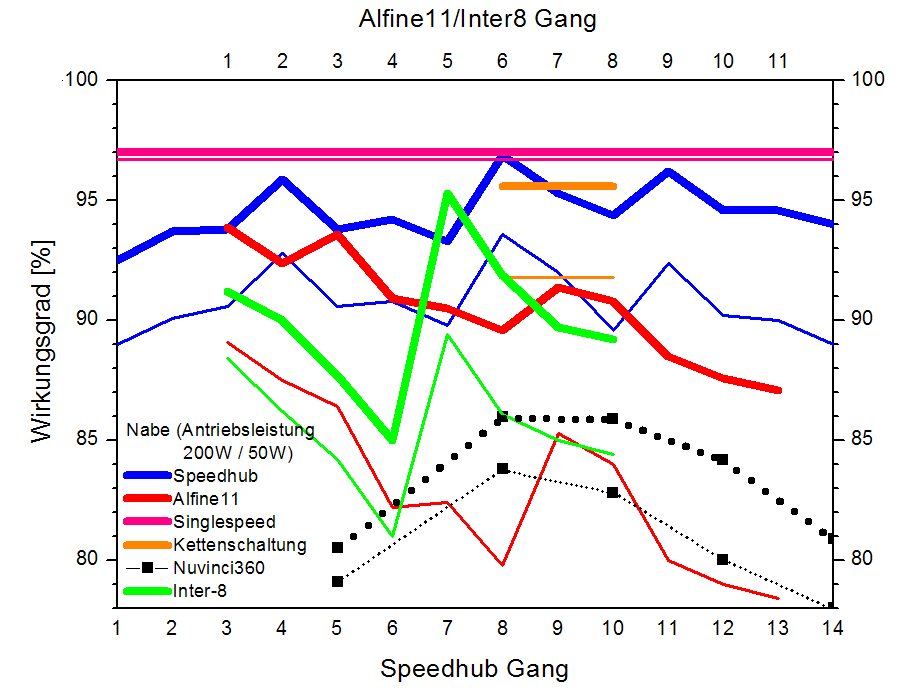

The German magazine Fahrrad Zukunft (Bicycle Future) published efficiency tests of various internal gear hubs. They found that at 200 watts (a fit person putting some effort in) the Shimano Alfine Inter 11 has a efficiency of 94% in the lowest gear and 87% in the highest gear. Like other drive trains the efficiency decreases at lower watts and becomes more variable as the resistance of other parts of the drive train remains the same and take up a large part of the total resistance.

The tests were conducted using a home built testing rig, and comes with some disclaimers. There are many variables influencing the efficiency, there was a limited sample size and the data had quite a bit of noise. Variables include manufacturing differences, how worn the parts is and the kind of lubricants used. All these factors can influence the efficiency. Even the single speed drive train only has an efficiency of 96% in these tests. A well maintained derailleur gear drivetrain would be able to get close to that, depending on the added drag by the derailleur jockey wheels and the chainline.

The Rohloff Speedhub is the most efficient internal hub, it's efficiency was measured to be between 87% and 94%. It is more efficient in the medium/high gears. In some of the lower gears its performance is equal to the Alfine 11.

The 18 speed Pinion gearbox is less efficient in lower gears and more efficient in the higher gears. The 8 speed Alfine/Nexus hubs are a mixed bag, with a highly variable efficiency, lower in most gears, but exceeding even the Rohloff by peaking at 96% in the 7th gear.

In conclusion, the Rohloff Speedhub has the a greatest range, it has a higher or equal efficiency in every gear, and is the best of all internal gear hubs in this test. The Alfine 11 takes second place. It excels in the 3 lowest gears. When climbing up a hill, you need every bit of power, so it seems like a fair compromise that you get less efficiency in the higher gears which you will use on the way down, or with the wind in your back when high efficiency is less of a necessity.

- Efficiency tests of various internal gear hubs (in German)

- Efficiency tests of various internal gear hubs - part 2 (in German)

- Comparison of the "upper class" of internal gear hubs: Alfine 11, NuVinci and Rohloff (in German)

Reliability

Since the hub has been on the market for a few years there is little information about the long term reliability.

On the internet there are various anecdotal reports of hub failure, but there are no statistics on how common this is, and under which circumstances the failure occurred.

Tell me how (un)reliable your hub is!

To provide better information about the long term reliability of this hub I am looking for input from you. If you have used this hub for more than a year (the longer the better), or have any failures to report please contact me and tell me how much distance you covered, and what maintenance schedule was kept. I am especially interested in reports from people who service multiple hubs.

Compared to Rohloff Speedhub

The Rohloff Speedhub has proven itself to be quite reliable over the years. In 2011, when the Alfine 11 speed was new, Elan, the importer for Rohloff hubs displayed various internal gears and bearings of both hubs at the Bike Motion trade show, to show that the beefier components for the Rohloff are more durable.

The article states that helical gears that Shimano uses for smoother and quiet shifting wear faster and are less efficient. One commenter on the page points out that helical gears have been used successfully in transmissions for automobiles, and that with proper lubrication they work fine.

Another commenter points out that that Rohloff's lowest ratio is 0.279 while it is 0.527 for the Shimano hub. This means that more torque is generated in the lower gears, with the same power input, put more strain on the transmission and requiring sturdier components.

It is also pointed out that Rohloff markets its hub for off-road use, while Shimano does not. When used according to instructions of the manufacturer there is little reason to assume the Shimano hub will be less reliable.

- Why Rohloff is better than Shimano (in Dutch)

My Own Experience

I have ridden my bicycle with the Alfine Inter 11 hub for two years, almost daily. In addition I have also maintained the hub on my girlfriend's bicycle. So far both hubs have been 100% reliable, with no noticeable changes to the shifting performance.

Known problems

Since Shimano does not publish any information about failure rates and problems. It is unclear how widespread issues are.

Leaking oil

It is normal for the hub to slowly leak oil over time. That is why the oil needs to be changed as part of a normal maintenance cycle. My own experiences and many reports on the internet indicate that the amount of oil leaking varies per hub. Some owners have had so much oil leaking that it covered the disk brake rotor, and had the hub replaced under warranty for it. Some people have suggested that there is a quality control issue with the seals, some hubs come with bad seals and leak excessively.

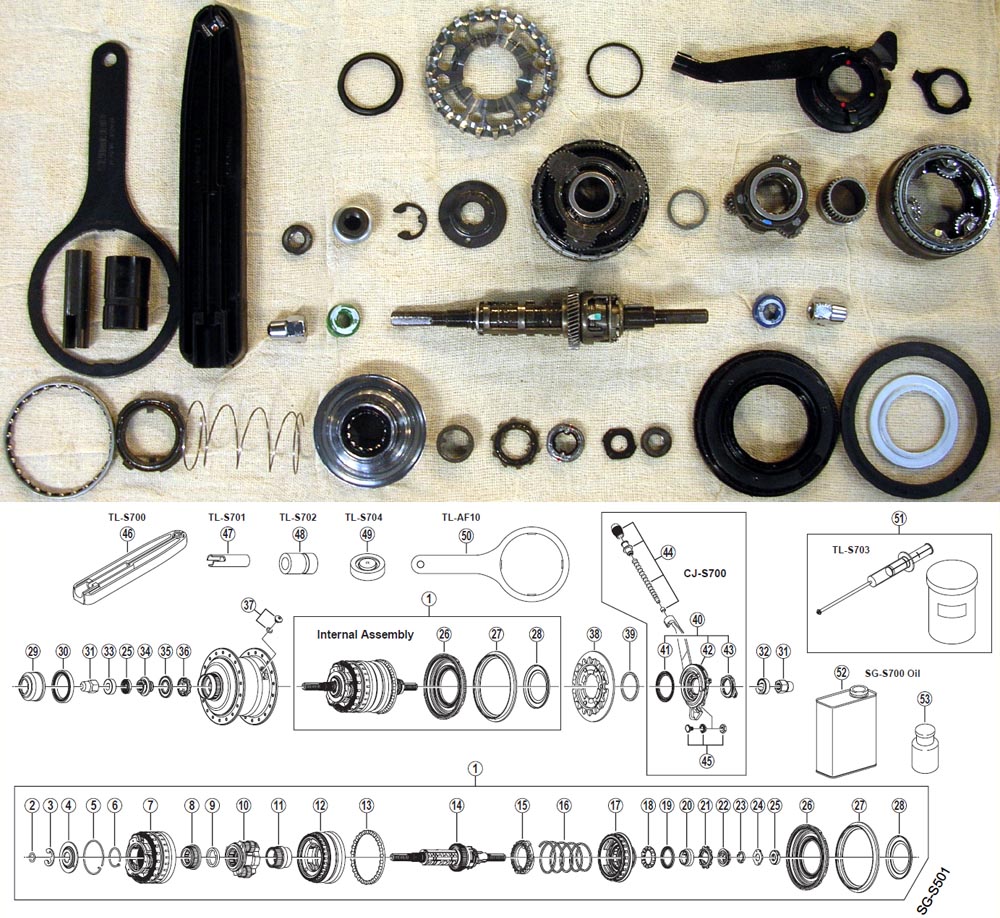

Internals

The inside of the Alfine Intern 11 contains an axle with pawls that move the gears around in order to switch gears. Some of the gears are helical, allowing the teeth to grab each other more easily while shifting. When switching between the sixth and seventh gear the clutch moves from the right side further towards the middle.

The links below do a good job of explaining the internal workings:

- Schematics of inner workings of Shimano Alfine inter 11

- Promotional video about the workings of Shimano Alfine inter 11

- Video of internal assembly turning and shifting

- Video of gear selector axle in action

Modifications

Weight Reduction

To shave of some extra grams you can replace some of the steel parts with titanium replacements. Planet Titanium sells a set with nine parts of mostly screws and washers. They reduce the weight from the original parts from 78.6 to 44.8 grams. Which is a reduction of 33.8 grams. However, for about one euro per gram you can probably find more effective upgrades to other parts of your bicycle first. The 9 part set is for the Alfine 11 speed. Apparently other light weight replacement parts like a carbon fiber cassette joint and a titanium screw for the shifter are in development.

Downloads

- Shimano Alfine 11 maintenance manual (PDF)

- Shimano Alfine 11 SL-700 Trigger shifter installation instructions (PDF)

- Shimano Alfine 11 SG-S700 hub installation instructions (PDF)

- Shimano Alfine 11 SG-S7001 parts list - Revision from July 2017 (PDF)

Reviews

- Shimano Alfine 11 hub gear and shifter review on road.cc

- Shimano Alfine group review by Bicycle Times Magazine

- Video review by Road.cc on Youtube

- Customer reviews on Amazon.com

- Riding experiences on Alseasonscyclist.com

- MTB Review: 2011 Shimano Alfine 11 Internal Gear Hub

- Shimano Alfine 11 short term review

If you have any suggestions for additions or corrections to this article please contact me.